Texas hdpe pipe manufacturer: Eco-Friendly Practices

Wiki Article

A Comprehensive Overview to the Various Usages of HDPE Pipeline in Construction and Market

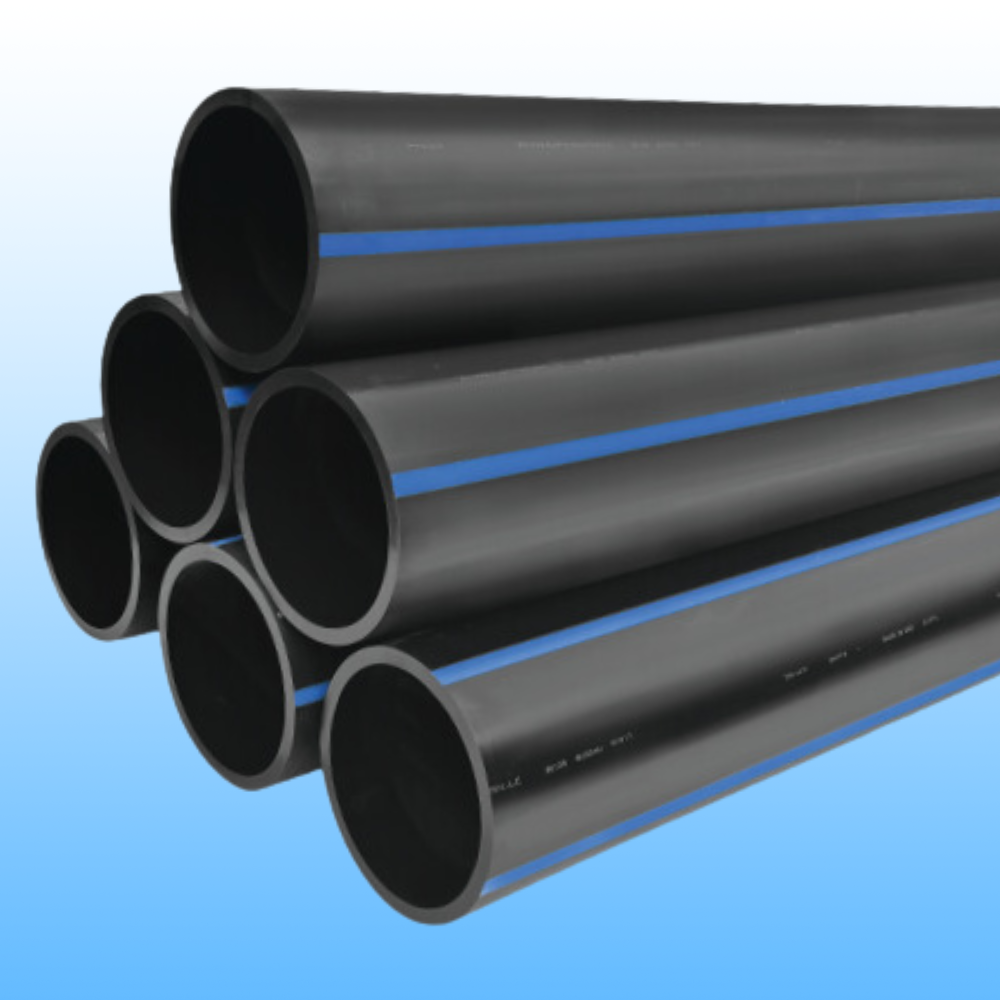

HDPE pipes have actually arised as a crucial component in contemporary building and industrial applications. Their unique residential properties, such as resistance to rust and light-weight layout, make them ideal for a wide variety of uses. From water supply systems to agricultural watering, HDPE pipelines supply options that improve performance and sustainability. Understanding their varied applications is crucial for specialists wanting to maximize infrastructure. What specific benefits do these pipes offer each market?Supply Of Water and Circulation Systems

Water supply and circulation systems are essential components of city framework, often depending on high-density polyethylene (HDPE) pipelines for their longevity and effectiveness. These systems transport potable water from treatment facilities to consumers, making certain ease of access and safety. HDPE pipelines are favored for their resistance to deterioration, chemicals, and severe temperature levels, which boosts their durability and minimizes upkeep prices. In addition, their lightweight nature permits simpler installment and transport, making them excellent for various urban and country applications.The adaptability of HDPE pipelines enables them to be mounted in tight areas and around obstacles, minimizing the need for considerable excavation (hdpe pipe fittings Midland TX). Additionally, their smooth indoor surface decreases friction losses, boosting water flow prices. As cities proceed to grow, the need for reliable supply of water systems boosts, positioning HDPE pipes as a sustainable service for contemporary facilities projects. Their tested performance history makes them a preferred selection amongst engineers and urban planners alike

Wastewater Monitoring and Therapy

Efficient wastewater management and therapy are necessary for maintaining public health and wellness and environmental top quality. HDPE pipes play a crucial duty in this procedure due to their sturdiness, resistance to corrosion, and ability to hold up against harsh chemicals. These pipelines are generally made use of in different applications, including sewage systems, stormwater drain, and wastewater treatment centers. Their lightweight nature helps with much easier installation and transportation, reducing labor expenses and time.On top of that, HDPE pipelines have a smooth indoor surface area that reduces rubbing loss, advertising effective circulation prices. They are also less vulnerable to leakages and failures compared to traditional products, ensuring that pollutants are included effectively. Moreover, their versatility permits versatility in various dirt problems, making them suitable for varied ecological settings. As sectors significantly prioritize sustainable methods, using HDPE pipelines in wastewater management systems straightens with objectives for decreasing ecological effect and improving source recovery.

Agricultural Irrigation Solutions

In farming settings, reliable irrigation solutions are essential for maximizing crop yields and handling water resources. HDPE (High-Density Polyethylene) pipes play a crucial role in modern irrigation systems because of their longevity, flexibility, and resistance to rust. Their capacity to endure high stress makes them ideal for both surface and subsurface irrigation applications, making sure consistent water circulation throughout fields.Farmers can make use of HDPE pipelines in drip irrigation systems, which deliver water straight to plant origins, lessening wastefulness and advertising healthy and balanced growth. Additionally, these pipes are lightweight and simple to mount, minimizing labor prices and setup time. Their lengthy life expectancy and low maintenance requirements further enhance their allure in agricultural methods.

home HDPE pipelines are ecologically pleasant, as they can be recycled and do not leach damaging chemicals right into the soil. This makes them a lasting choice for farmers intending to embrace environment-friendly farming approaches while making best use of performance.

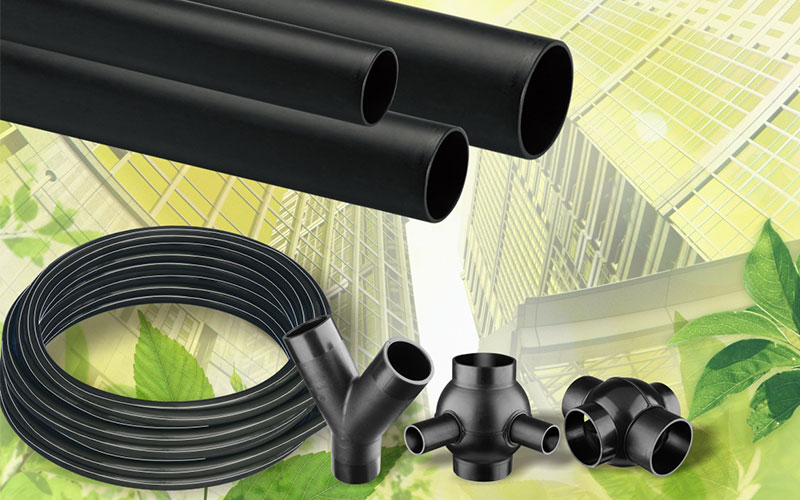

Industrial Applications and Procedures

Convenience is a hallmark of HDPE pipelines, making them vital in numerous industrial applications and procedures. These pipelines are commonly utilized in chemical handling sectors due to their exceptional resistance to a large range of harsh materials. HDPE's lightweight nature, incorporated with high tensile toughness, permits simple setup and long-term efficiency sought after atmospheres.In the oil and gas field, HDPE pipes play a crucial function in delivering hydrocarbons and gases, thanks to their longevity and versatility - American Plastics HDPE Pipe Manufacturing. Additionally, they are used in mining operations for the transport of slurry and other products, where standard piping systems may fail

HDPE pipes are progressively utilized in manufacturing centers for water supply lines and wastewater management. Their ability to endure severe temperature levels and pressures makes them suitable for a variety of industrial processes. On the whole, HDPE pipelines contribute substantially to performance and security throughout varied commercial applications.

Stormwater Monitoring and Drain Equipments

Stormwater administration and drain systems are crucial parts in city framework, made to manage excess rainfall and reduce flooding threats. High-density polyethylene (HDPE) pipes are significantly utilized in these systems as a result of their toughness, versatility, and resistance to corrosion. These pipes successfully move stormwater away from booming areas, decreasing surface overflow and protecting against waterlogging.HDPE's light-weight nature facilitates much easier installation, lowering click now labor prices and building time. Additionally, its resistance to chemicals and environmental stressors guarantees durability and dependability in numerous environments. Along with typical drain applications, HDPE pipes are likewise employed in innovative services such as environment-friendly infrastructure, which includes rainfall yards and permeable pavements.

Frequently Asked Questions

How Does HDPE Pipeline Contrast to PVC Pipeline in Expense?

As a whole, HDPE pipe often tends to be a lot more costly than PVC pipeline as a result of its improved sturdiness and versatility. Long-term cost considerations, such as upkeep and life expectancy, may favor HDPE in particular applications.What Is the Life-span of HDPE Piping Under Varying Problems?

HDPE pipelines usually have a life-span of 50 to 100 years, depending on environmental conditions, installment techniques, and use. Aspects such as temperature level, dirt kind, and exposure to chemicals can greatly affect their resilience.Can HDPE Pipeline Be Recycled After Use?

Yes, HDPE pipelines can be reused after usage. The reusing procedure includes melting down the product, allowing it to be repurposed right into new items, thereby advertising sustainability and reducing ecological influence linked with plastic waste.Are There Any Type Of Details Setup Challenges With HDPE Pipelines?

Setup challenges with HDPE pipes consist of proper jointing methods, guaranteeing ample trench conditions, and handling thermal development. Additionally, proficient labor is needed to manage specialized devices, which can make complex the installment procedure in different environments.

What Accreditations Should I Look for When Getting HDPE Water Lines?

When purchasing HDPE pipes, one should seek qualifications such as redirected here ASTM, AASHTO, and ISO, which verify high quality and compliance with sector criteria, guaranteeing sturdiness and performance in different applications. - hdpe pipe fittings Midland TXReport this wiki page